The Evolution of Adhesive Technologies

The journey of adhesive technologies has been marked by constant change and innovation. From natural resins used in ancient times to the sophisticated compounds of today, adhesives have steadily evolved. This continuous improvement has been driven by the need for stronger, more reliable, and safer bonding solutions.

In the early 20th century, adhesives took a significant leap forward with synthetic polymers. These new materials expanded the possibilities for adhesion, durability, and resistance to the elements. Fast forward to the 21st century, and we see adhesives that are not just bonding agents but integral parts of design and functionality. Smart adhesives that react to environmental changes and offer re-workability have become engines of innovation in various industries.

The current trend is the drive toward sustainability. Eco-friendly adhesive technologies are not just a niche market anymore but are entering the mainstream. Companies now prioritize renewable sources and environmental impact in their adhesive formulations. These innovations highlight a clear shift: the evolution of adhesive technologies is not just about bonding strength, but also about contributing to a greener future.

As we move through 2024, adhesive technologies are set to become more personalized and tailored to specific applications. We’re witnessing a push for bio-based adhesives that come from natural, renewable sources. Adhesive technologies that once seemed futuristic, such as those activated by light or designed for extreme conditions, are becoming commonplace. This evolution underscores the industry’s commitment to meeting the ever-growing demands of consumers and the planet.

Key Trends Shaping the Future of Adhesives

The adhesive industry is evolving rapidly. New trends promise to shape the future in exciting ways. Companies and researchers focus on innovation to meet users’ needs and minimize environmental impact.

Eco-Friendly Materials

Sustainability stands out as a key driver. Eco-friendly materials are at the forefront of research and development. Adhesive producers are embracing renewable resources to create products with less ecological footprint. They are moving away from petroleum-based adhesives to ones made from plants or recycled materials.

Improved Performance and Durability

Users demand adhesives that last longer and perform better. The industry is responding with adhesives that withstand extreme temperatures and resist moisture. Items fixed today need to stay intact for years, without the need for constant repairs.

Smart Adhesives

Adhesives are getting smarter. New products can react to their environment. Some adhesives can change their properties in response to heat or light. This creates opportunities for innovation in sectors like electronics and construction.

Tailored Adhesives for Specific Industries

Customization is another growing trend. Industries have unique bonding needs. Adhesive technologies are now being designed to address these specific demands. Whether it’s for medical devices or aerospace applications, tailor-made solutions are on the rise.

Regulatory Compliance

Regulations influence the adhesive sector. Companies have to ensure their products comply with global standards for safety and environmental protection. This pressures the industry to innovate while adhering to stricter guidelines.

These key trends in adhesive technologies reflect the dynamic nature of the industry. As they continue to unfold, we expect to see a new generation of adhesives. These products will not only bond materials but will also contribute to a sustainable future and meet stringent performance criteria.

Breakthroughs in Eco-Friendly Adhesive Solutions

The adhesive industry has made giant strides in eco-friendly solutions. Recent breakthroughs showcase a commitment to sustainability without compromising on strength or durability. Let’s explore these innovations that are setting new standards for eco-conscious bonding.

Bio-Based Adhesives

Researchers have developed adhesives derived from natural resources. These bio-based products reduce reliance on fossil fuels. They offer a lower carbon footprint. Companies are using materials like plant oils and cellulose. These materials come from renewable sources. This shift is key to sustainable manufacturing.

Recycled Content Adhesives

Recycled materials are now part of adhesive recipes. This approach reduces waste. It extends the life of existing materials. Adhesive producers are mixing recycled plastics and rubber into their formulations. This innovation supports a circular economy.

Water-Based Adhesives

Solvent-based adhesives are losing favor due to environmental concerns. Water-based alternatives are gaining popularity. They emit fewer volatile organic compounds. This change improves workplace safety and environmental health.

Biodegradability Advances

The industry is not just making adhesives from green materials. They are also making them biodegradable. These products can break down naturally. They minimize the long-term environmental impact. This advancement is critical for applications like packaging.

Low-Emission Adhesive Technolgies

Indoor air quality is important for health and safety. Adhesive suppliers are addressing this by reducing emissions from their products. Low-emission adhesives maintain high performance. Yet, they contribute less to air pollution. This is essential in confined or poorly ventilated spaces.

These breakthroughs in eco-friendly adhesive solutions are transforming the industry. Companies are balancing the need for effective adhesives with environmental responsibilities. As adhesive technologies continue to progress, we can expect even more innovative and sustainable options to emerge.

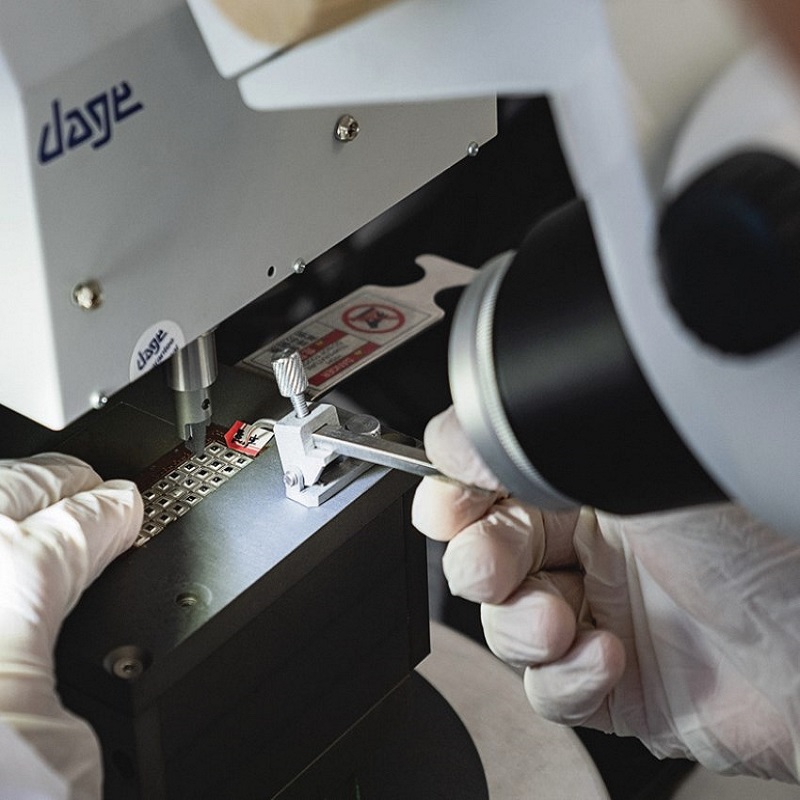

Advancements in Industrial Adhesive Applications

Industrial settings demand robust adhesive technologies. Rapid advancements have led to adhesives that meet industry-specific needs.

High-Strength Adhesives

Today’s industrial adhesives bond stronger than ever. They handle heavy loads and intense stress. This strength is vital in construction and automotive sectors.

Heat-Resistant Adhesives

Advancements have produced adhesives that withstand extreme heat. These are crucial for applications in machinery and aerospace.

Chemical-Resistant Adhesives

New formulas resist harsh chemicals. They ensure durable bonds in environments like laboratories and manufacturing plants.

Flexible Adhesives

Industries need flexible yet strong adhesives. These new products can stretch without losing their grip. It’s a big leap for dynamic environments.

Faster-Curing Adhesives

Time is money in industry. Adhesive technologies that cure quickly are revolutionizing efficiency. They speed up production lines.

Vibration-Damping Adhesives

Machinery generates vibrations. Adhesives that dampen these vibrations improve machine longevity and performance.

These advancements in industrial adhesive applications show the industry’s push for innovation. They are creating solutions that are not just stronger or faster, but also tailored for specific challenges. As adhesive technologies continue to evolve, industries can expect even more specialized products to enhance their operations.

Role of Nanotechnology in Adhesive Enhancements

Nanotechnology is influencing adhesive technologies significantly. It’s enabling stronger, more versatile adhesives. Here’s how nanotechnology is making an impact.

Nano-Additives for Increased Strength

Nano-additives can greatly enhance adhesive properties. They are tiny particles that make the bond incredibly strong. Even in small amounts, they contribute to the durability of adhesives.

Improved Adhesive Properties

Nanotechnology allows for more precise control over adhesive characteristics. Through nanoscale manipulation, adhesives gain improved thermal and chemical resistance. This advancement suits high-performance needs.

Eco-Friendly Nano-Adhesives

Eco-friendly adhesive technologies benefit from nanotechnology. Nanoscale innovations help create bio-based and biodegradable adhesives. This aligns with sustainability trends in the industry.

Nano-Enabled Smart Adhesives

Smart adhesives now include nanotechnology. This integration allows adhesives to respond to environmental stimuli such as temperature changes.

Enhanced Safety and Non-toxicity

Nanotechnology-focused adhesives are becoming safer. They are engineered to be non-toxic and reduce health risks in the workplace.

Nanotechnology pushes the boundaries of adhesive enhancements, leading to stronger, safer, and smarter adhesive solutions. Its role is vital in producing next-generation adhesives that cater to advanced industrial applications and environmental concerns.

Impact of Artificial Intelligence on Adhesive Manufacturing

The manufacturing landscape of adhesive technologies is undergoing a significant transformation, thanks to the integration of Artificial Intelligence (AI). AI is influencing the way adhesive products are designed, tested, and produced. Here are some of the key impacts of AI on adhesive manufacturing that we are seeing in 2024:

AI-Driven Design and Prototyping

AI facilitates quicker adhesive design and prototyping. Leveraging machine learning, manufacturers can predict outcomes and fine-tune adhesive formulas for particular applications before they go into production.

Enhanced Quality Control

With AI, quality control processes are more thorough. Automated systems inspect adhesives for consistent quality, which minimizes the chance of defects reaching the market.

Supply Chain Optimization

AI helps in optimizing the adhesive supply chain. It forecasts demand, manages inventory efficiently, and reduces waste, which all lead to cost savings.

Predictive Maintenance

Predictive maintenance of machinery, guided by AI algorithms, minimizes downtime in the manufacturing process. This enhances productivity and reduces operational costs.

Customized Production Runs

Manufacturers use AI to support smaller, customized production runs of adhesives. This meets the growing demand for bespoke adhesive solutions in various industries.

The impact of AI on adhesive manufacturing is transformative, leading to smarter, faster, and more reliable production processes. As AI technologies continue to advance, they will play an ever-greater role in the innovative march of adhesive technologies.

New Frontiers in Biodegradable and Bio-based Adhesives

The adhesive industry is seeing a surge in biodegradable and bio-based options. As the world focuses more on environmental sustainability, the development of adhesives that can break down naturally has become a priority. This section highlights the latest innovations in this area.

Embracing Renewable Resources

The push towards renewable resources is leading the charge in creating biodegradable adhesives. These materials are derived from natural, sustainable sources like starch, natural rubber, and other plant-based compounds. The advantage of using such resources is twofold: they are kinder to the environment and they reduce our dependence on non-renewable, petrochemical-based adhesives.

Technological Innovations in Bio-adhesives

Technology is aiding the creation of bio-based adhesives that don’t lag behind traditional ones in performance. Innovators are unlocking the potential of natural polymers to create bonds that are strong yet reversible and decomposable. This is key for industries that prioritize easy disposal and recycling.

Meeting Industrial Demands

Biodegradable and bio-based adhesives are not just for simple applications; they are also making their way into heavy industries. The automotive and construction sectors are beginning to adopt these advanced adhesives. They meet the rigorous demands of these industries while aligning with their sustainability goals.

Overcoming Challenges in Performance

One of the hurdles in the widespread adoption of biodegradable adhesives is performance in extreme conditions. But recent advancements suggest a turning point. New formulations show impressive resistance to water, temperature fluctuations, and mechanical stresses.

The momentum in developing biodegradable and bio-based adhesives is reshaping the future of adhesive technologies. As the industry evolves, it remains committed to meeting the dual objectives of superior performance and environmental responsibility. With continued research and development, biodegradable and bio-based adhesives are set to become the gold standard in the not-so-distant future.

Challenges and Future Projections for Adhesive Technologies

As we continue to push the envelope in adhesive technologies, several challenges await us. At the same time, the future holds promising advancements that will shape the industry.

Addressing Environmental Concerns

One major challenge is the environmental impact of adhesives. Manufacturers must minimize carbon footprints and pollution. They need to ensure that adhesives are as eco-friendly as possible.

Enhancing Bonding Strength and Durability

Users expect adhesives to last longer while maintaining strength. Researchers are focusing on new chemical formulations to meet these demands. They aim to provide reliability across various conditions.

Developing More Sophisticated Smart Adhesives

Smart adhesives must evolve to better respond to environmental changes. The goal is for these adhesives to adjust their properties for optimal performance. Innovation in this sector is vital.

Balancing Cost and Performance

A balance between cost-efficiency and superior performance is crucial. Producers are seeking ways to deliver high-quality adhesives without a high price tag. Affordable excellence is a key target.

Regulatory Compliance

As regulations tighten, compliance becomes tougher. Adhesive companies will have to adapt while still driving forward with innovations.

As we look to the future, we anticipate tremendous growth in renewable and smarter adhesives. The trends point toward adhesives that are not only powerful but also responsible. We foresee stronger, greener, and more responsive adhesives emerging. By overcoming today’s challenges, adhesive technologies will continue to revolutionize bonding in countless industries.